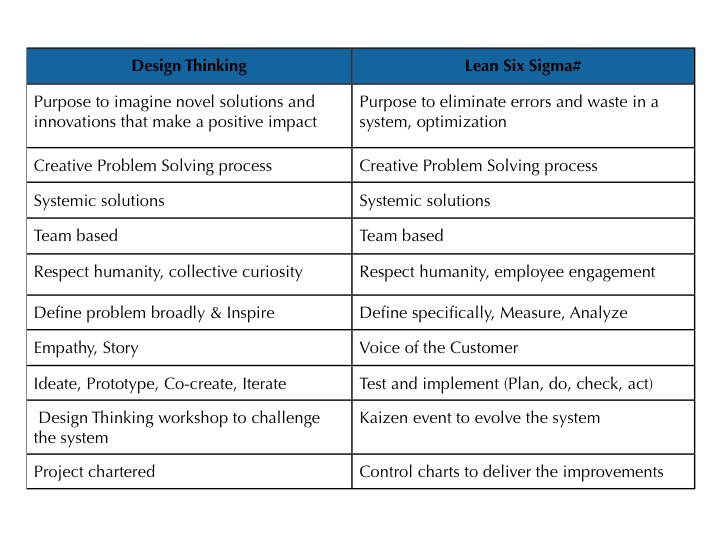

Recently, I attended a training class to learn more about Lean Six Sigma. I had heard of it often from my manufacturing and engineering friends; and when they would ask how design thinking was similar or different, I was stumped. After all, they sound similar–both are about making things better, improvement, innovation even. So, I attended my training with wide eyes and ears hoping to learn the answer to such a simple question. I was pleased to see that Design Thinking and Lean Six Sigma were “kissing cousins,” philosophically similar, yet unique. Here is what I deduced:

#Lean Six Sigma has been around since early 2000s when Michael George published it in his book, Lean Six Sigma: Combining Six Sigma with Lean Speed. It is not the same capability as the 2011 emerging concept Lean Start Up proposed by Eric Ries, which is growing in popularity recently.

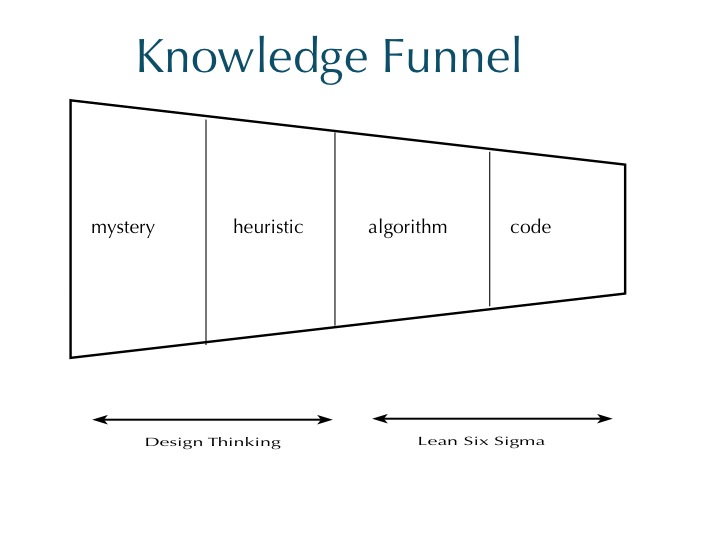

Fundamentally, Design Thinking and Lean Six Sigma are focused on different ends of the Knowledge Funnel (see below) as Design Thinking is about imagining and Lean Six Sigma is about optimizing the current system and evolving it. The Knowledge Funnel is explained in the book, The Design of Business, Why Design Thinking is the Next Competitive Advantage by Roger Martin. I have found that Design Thinking is well suited for helping advance/innovate mysteries and hueristics whereas I think Lean Six Sigma is uniquely suited to advance practices in algorithm and code. Net, both approaches are necessary and useful….it’s just a matter of when to use each.  Both approaches use creative problem solving approaches as part of their solution approach but Design Thinking looks beyond the problem being solved to see the system as a whole in context. Both use customer data; however, the type of customer data and its purpose differ. Lean Six Sigma considers customer data on the defined and measurable problem whereas Design Thinking leverages the customer, or non customer’s, human story and broader needs as inspiration to discovering opportunities. Both believe in testing their ideas and learning quickly, Design Thinking’s idea of a test is a lower resolution prototype that can invite the customer to co-create and evolving this prototype quickly into a testable proposition. Lean Six Sigma lives in the world of highly measurable deliverables where control charts are possible. Design Thinking lives in the world of imagination and possibilities. The output of a Design Thinking process typically gets chartered, further developed and assessed before being implemented into a system that can be highly measured and controlled. Organizations need Design Thinking and Lean Six Sigma. They are related; and yet, they are completely different. Together they make for good business. Cindy

Both approaches use creative problem solving approaches as part of their solution approach but Design Thinking looks beyond the problem being solved to see the system as a whole in context. Both use customer data; however, the type of customer data and its purpose differ. Lean Six Sigma considers customer data on the defined and measurable problem whereas Design Thinking leverages the customer, or non customer’s, human story and broader needs as inspiration to discovering opportunities. Both believe in testing their ideas and learning quickly, Design Thinking’s idea of a test is a lower resolution prototype that can invite the customer to co-create and evolving this prototype quickly into a testable proposition. Lean Six Sigma lives in the world of highly measurable deliverables where control charts are possible. Design Thinking lives in the world of imagination and possibilities. The output of a Design Thinking process typically gets chartered, further developed and assessed before being implemented into a system that can be highly measured and controlled. Organizations need Design Thinking and Lean Six Sigma. They are related; and yet, they are completely different. Together they make for good business. Cindy

TAKE ACTION THIS WEEK:

Explore how these two disciplines relate. Pick the one you are less familiar with and have a coffee with someone who is skilled in that field. So, if you are familiar with Lean Six Sigma, take a design thinking practitioner to coffee or vice versa and talk about how the two relate. You might discover a new connection for yourself. If so, please share it with us.